Description

HardieBacker Board is an engineered tile backer board made from 90% portland cement and sand. It provides an exceptionally robust, dimensionally stable and rigid surface for tiling onto, that can accommodate up to 200kg/m² of tile hanging weight.

Whereas traditional sheet materials such as plywood and plasterboard are liable to break or disintegrate when wet, HardieBacker Board features outstanding moisture resistance and stays strong and firm, no matter how damp or wet it gets, protecting your bathroom against moisture damage. It is also protected by a 10-year limited product warranty.

Each HardieBacker Board measures 1200 x 800mm and is available in either 6mm or 12mm thicknesses. 6mm HardieBacker Board is for overboarding timber floors or existing plaster/masonry walls, 12mm is for use on stud walls and fire surrounds.

HardieBacker Board is easy to cut, using a HardieBacker Scoring Knife. Simply score the board firmly using a straight edge as a guide then pull the board edge upwards to snap the board. HardieBacker Board is ready to tile once installed, and just requires wiping down with a damp sponge to remove any dust prior to tiling. If using the boards in a wetroom, the installation should be tanked with a suitable waterproofing membrane and tape system prior to tiling.

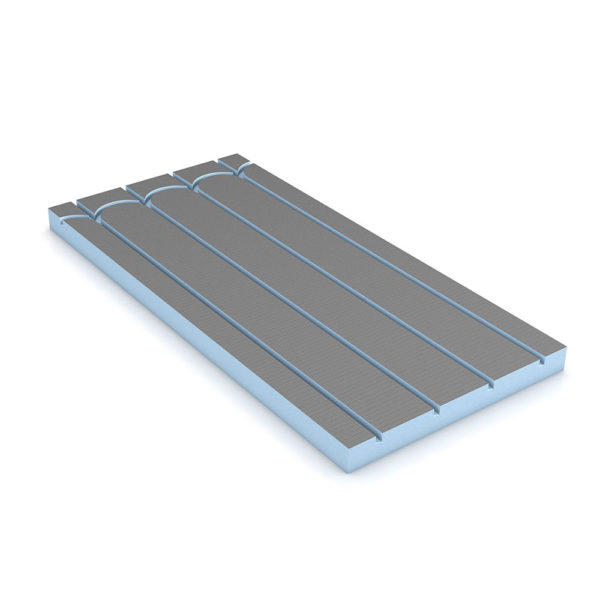

HardieBacker Boards are suitable for use with underfloor heating, and should always be placed between the structural timber floor and the heating element.

HardieBacker Board does not have to be finished with tiles. It can be painted, plastered, and even wallpapered.

Overlaying Timber Floors with HardieBacker Board 6mm:

Preparation: Ensure subfloor is structurally sound and not damaged. Replace any loose, warped or uneven sections of the floor. Make certain the subfloor has a clean and flat surface.

Installation: Apply a gap filling bed of tile adhesive to the subfloor using a 6 mm notched trowel. Embed the HardieBacker boards with a sliding motion firmly and evenly in the wet tile adhesive. Stagger all HardieBacker board joints in a broken bond or brick pattern. Never allow all four corners of boards to meet at one point. Do not align with subfloor joints. Leave a 3 mm gap between floor and wall edges, vanities, baths etc. Use HardieBacker Fixing Screws – fasten a minimum of 12 screws into the board (4 rows of 3 screws). Keep fixings between 15 mm from board edges and 50 mm from board corners. Fill the gap between floor and wall edges with good quality bathroom sealant.

Finishing Joints: Prior to setting the tiles, embed 50 mm alkali resistant Hardie Tape Fibatape across joints and feather tile adhesive to leave a 150 mm wide joint.

Overboarding Masonry Walls with HardieBacker Board 6mm:

Preparation: Remove all existing old dry lining. Wipe the back of the HardieBacker board to remove dust.

Installation: Place three vertical 10-12mm beads of HardieBacker Foam Fixing Adhesive evenly down the back of the board. Press board firmly against the wall into the desired position. Fasten the HardieBacker boards with 9 (6mm x 60mm) stainless steel screws into brown wall plugs. Screws should remain 100mm from the top and bottom edges and 50mm from the left and right edges. Do not overdrive the screws; it must be flush with the front of the board.

Finishing Joints: Prior to setting the tiles, embed 50mm alkali resistant Hardie™ Tape Fibatape across joints and feather tile adhesive to leave a 150 mm wide joint.

Overboarding plasterboard or plaster walls with HardieBacker Board 6mm:

Preparation: Locate existing studs with stud finder and mark the plasterboard or plaster.

Installation: Boards may be installed vertically or horizontally. Ensure all vertical joints are made on the centre of the studs. Leave a 3 mm gap between floor and wall edges and fill with a good quality bathroom sealant. Fix stainless steel screws (minimum 45 mm length) at 200 mm centres. Keep fixings 15 mm from board edges and 50 mm in from sheet corners. Set heads of fixings flush with the surface, without overdriving.

Finishing Joints: Prior to setting the tiles, embed 50 mm alkali resistant Hardie Tape Fibatape across joints and feather tile adhesive to leave a 150 mm wide joint.

Stud wall installation with HardieBacker Board 12mm:

Preparation: Stud centres can be set at a maximum of 600 mm. Ensure framing is structurally sound and not damaged.

Installation: HardieBacker Boards may be installed vertically or horizontally. Ensure all vertical joints are made on the centre of the studs. Leave a 3 mm gap between floor and wall edges and fill with a good quality bathroom sealant. Use 25mm or 35mm HardieBacker Fixing Screws at 200 mm centres. Keep fixings 15 mm from board edges and 50 mm in from sheet corners. Set heads of fixings flush with the surface, without overdriving .

Finishing Joints: Prior to setting the tiles, embed 50 mm alkali resistant Hardie Tape Fibatape across joints and feather tile adhesive to leave a 150 mm wide joint.

Click here to view this product on the Manufacturers website.