Description

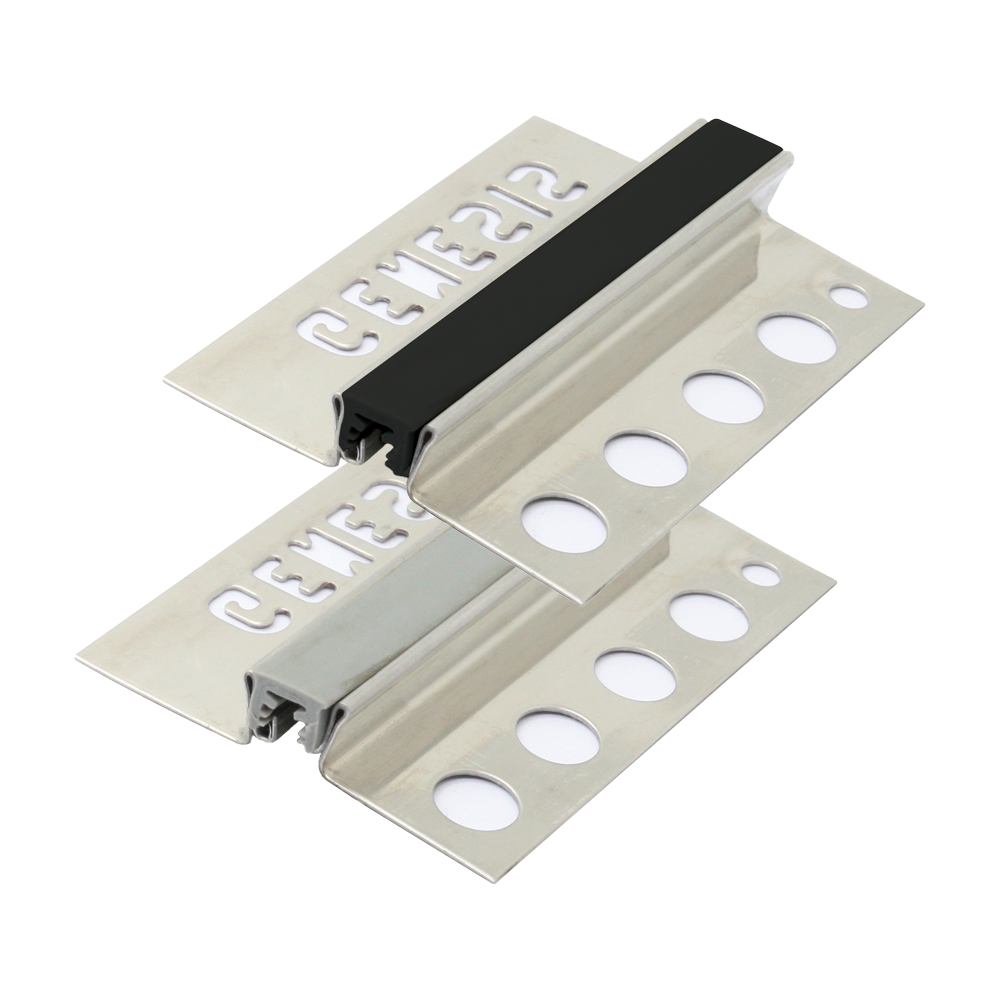

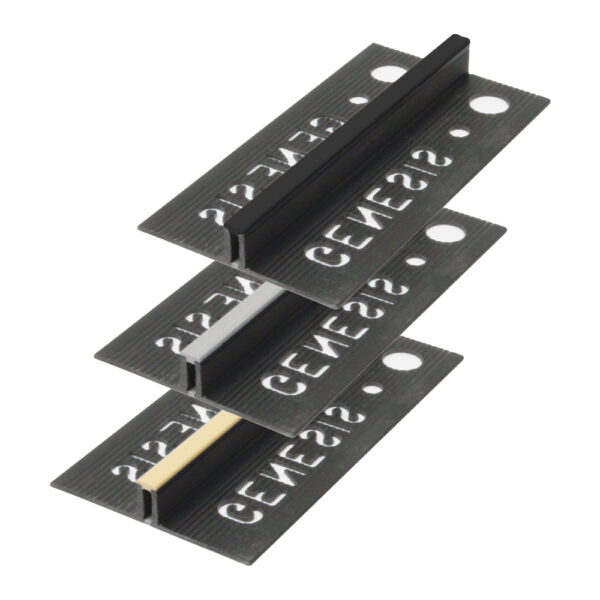

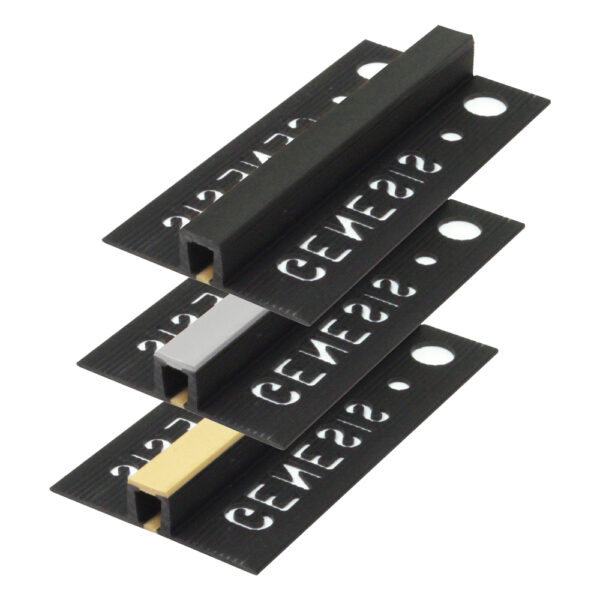

The Genesis MSS Stainless Steel Movement Joint with Removable Infill is a heavy duty stainless steel movement joint with a infill that can be removed and replaced thus saving expense if the joints require replacing in future. It is designed to provide heavy duty protection to the edge of the floor covering and a hygienic environment.

The Genesis MHS Stainless Steel Movement Joint is available with either a black or grey coloured infill, in 10mm or 12.5mmm internal height sizes. Each colour/size combination is supplied in 2.5 metre lengths.

Where to use:

Movement joints such as the Genesis MSS Stainless Steel Movement Joint must be installed in certain areas and positions to prevent tiles debonding from the substrate, industry guidelines suggest that the maximum field should be no more than 10m in each direction but in practice, depending on the individual applications it tends to between 5-8m. British Standards (BS) 5385 covers the requirements and methods for movement joints applications. Part 3: 1989-Section 3-19.1.1 states the building designer should assess the magnitude of any stresses and decide where movement joints should be located taking into consideration all the relevant factors. Movement joints must be installed directly above any changes in substrate or movement joints/gaps in the substrate.

Installation:

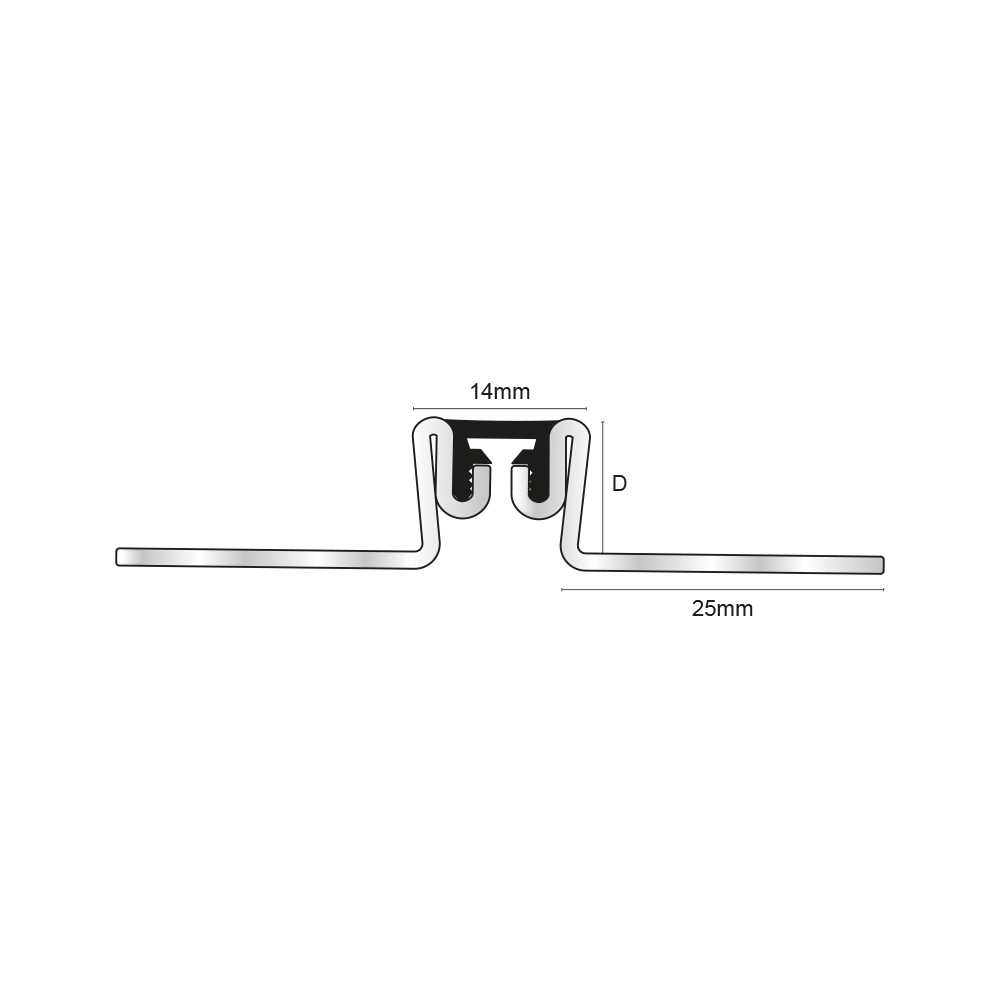

1. Ensure the correct depth of Genesis MSS Stainless Steel Movement Joint profile is selected according to the tile depth.

2. Using a suitable notched trowel spread tile adhesive onto the floor in accordance with the manufacturers guidelines.

3. Bed the profile firmly into the adhesive in the correct location – make sure that the adhesive penetrates the holes in the flange.

4. Spread the adhesive over the anchoring legs and bed the tiles firmly into the adhesive (best practice is for the profile to be approximately 1mm lower than the tile).

5. A grout joint should be left between the tile and the profile.

Maintenance:

The Genesis MSS Stainless Steel Movement Joint is made from stainless steel, which is a corrosion resistant chromium/nickel alloy steel that is strong and durable with excellent lustre. However, it is not rustproof, particularly in the harsh environment of a swimming pool. Chlorine and bromine used for sanitization are highly caustic chemicals for stainless steel and heat and humidity enhance the corrosiveness of these chemicals. Regular cleaning is the best way to prevent corrosion and add to the service life for your profiles and any other stainless steel equipment. The goal of your cleaning and maintenance program should be to keep the stainless steels protective chromium oxide layer intact. This is what prevents corrosion at varying stages of contamination.

Click here to view this product on the Manufacturers website.

Reviews

There are no reviews yet