Description

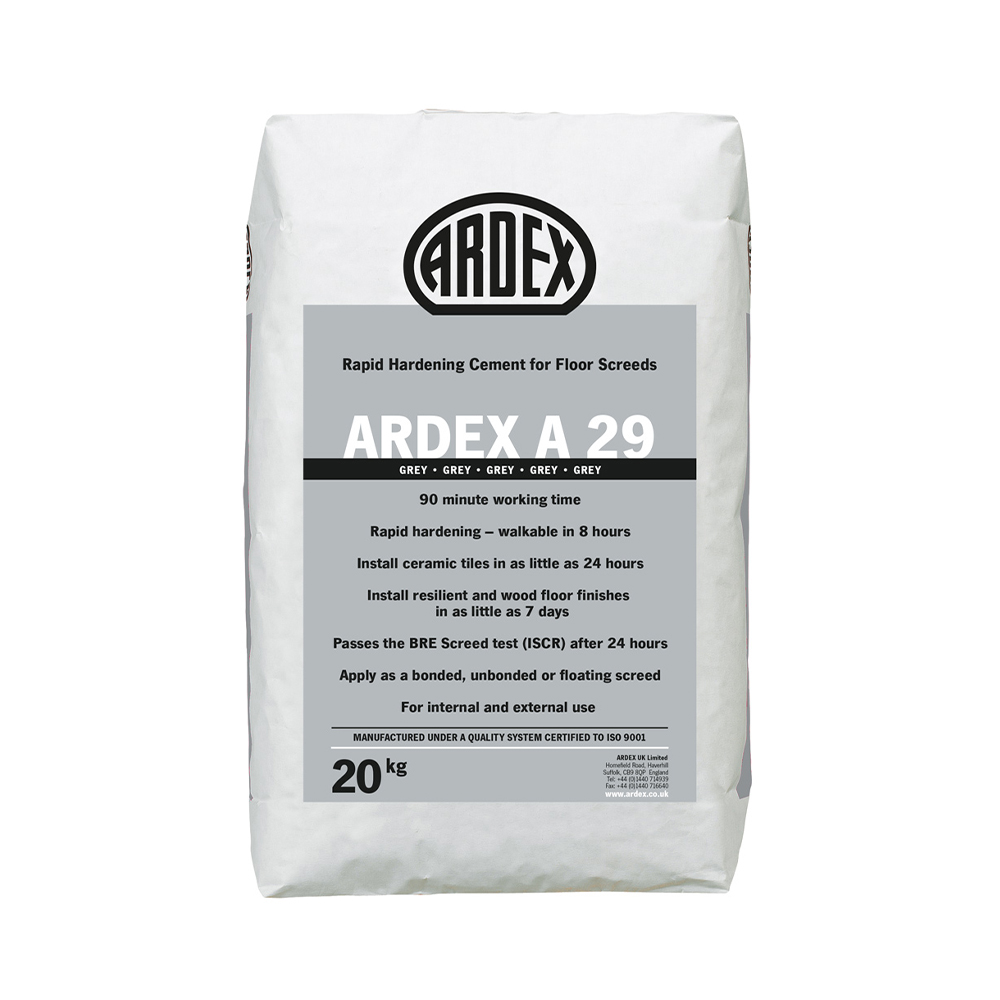

Ardex A29 Floor Screed Cement is a special cement for producing a rapid hardening floor screed for internal and external use which allows ceramic tiles to be fixed in as little as 24 hours, and natural stone and resilient floorcoverings in as little as 7 days.

Ardex A29 Floor Screed Cement is used to produce bonded, unbonded and floating screeds in internal or external locations. A 1:7 mix is suitable for most normal screeding situations. An Ardex A29 Screed passes the BRE Screed (ISCR) after 24 hours (tested on 50mm unbonded at 20°C).

Thickness:

Ardex A29 Floor Screed Cement should be applied at the conventional thicknesses for normal cement/sand screeds i.e. Minimum 20mm at 1:5 ratio and minimum 25mm at 1:7 ratio, (design thickness up to 40mm) for bonded screeds. Minimum 50mm for unbonded screeds. Minimum 75mm for floating screeds. 65mm in lightly loaded (domestic) locations.

Mix Proportions:

Please see product datasheet linked below for details.

Water:

Add sufficient water to obtain a workable mix. With an evenly graded, fairly dry sand, the water requirement will normally be up to a maximum of 11 litres per 20kg bag of Ardex A29 (including the water contained in the sand/ aggregate).

Mixing:

When a sample of mixed Ardex A29 mortar is squeezed in the hand the sample should retain its shape and not crumble, the hand being left slightly moist. When a sample is compacted on the base, no film of water should form on the surface. Mix to a normal screed mortar consistency. If a mixer is used it should be a pan, trough or other forced action type. Normal ‘free-fall’ mixers are not suitable for mixing semi-dry screed mortars. Use clean equipment and do not use other cements, lime or screed additives etc., in the mix.

Coverage:

Approximately 0.27kg Ardex A29 cement per m² for each millimetre of screed thickness using a 1:7 mix.

Application:

The working time of the mixed Ardex A29 mortar is approximately 90 minutes at 20°C, therefore mixing, placing, compaction and trowelling off must proceed without delay. The amount of mortar mixed and the area to be screeded should be limited so that trowelling off and finishing can be completed within the working time.

Where a new bay is laid against a set and hardened screed it is recommended that such daywork joints are vertical and treated with the grouting slurry and may be tied together with steel reinforcement. Apply an Ardex A29 Screed at temperatures of 5°C and rising.

Application on a floor heating system: When an Ardex A29 screed has been laid on a hot water floor system, 7 days should be allowed to elapse before heating the water up to a temperature of 25°C and maintained for a further 3 days. The maximum floor temperature should then be used and maintained for a further 4 days. In doing so draughts must be avoided. The floor should then be allowed to cool down to room temperature (above 15°C) before laying floorcoverings.

Drying Times:

A bonded Ardex A29 Screed is normally ready to receive ceramic tiles after 24 hours. For unbonded and floating screeds, 7 days drying time is required, or a moisture reading of <2% by the Carbide method, before fixing ceramic tiles.

Natural stone tiles can be fixed after 7 days. An Ardex A29 Screed can usually receive resilient and wood floorcoverings after 7 days, or when a moisture reading of <2% by the Carbide method is recorded.

The time taken to harden, and the drying time of the Ardex A29 Screed, is determined by screed thickness and ambient conditions on site. Low temperatures will slow down the rate of hardening whilst high temperatures will accelerate hardening, thus reducing the working time.

Technical Data:

Weight of fresh mortar: approx. 2kg/litre

Working time at 20°C: approx. Up to 90 minutes

Compressive strength:

28 days (1:7 mix): 30 N/mm²

28 days (1:5 mix): 40 N/mm²

Click here to view this product on the manufacturers website.

Reviews

There are no reviews yet