Description

Mapei Kerapoxy CQ Epoxy Tile Grout is a two-component epoxy grout that is easy to apply and has excellent cleanability, with a bacteriostatic agent and BioBlock® technology, ideal for grouting ceramic tiles and mosaics. Can also be used as an adhesive. Available in 3kg tubs.

Mapei Kerapoxy CQ Epoxy Tile Grout is certified by the University of Modena (Italy) according to ISO 22196:2007 standards as a grouting mortar protected against the formation and proliferation of micro-organisms.

Mapei Kerapoxy CQ Epoxy Tile Grout is for internal and external grouting of ceramic, stone material and glass mosaic floor finishes. It is particularly suitable for grouting large areas where easy application and cleaning is required. Mapei Kerapoxy CQ allows you to create floors, walls and worktops, etc. in compliance with the HACCP system and the requirements of EC Regulation No. 852/2004 regarding hygiene and foodstuffs. Mapei Kerapoxy CQ Epoxy Tile Grout is also suitable for acid-resistant bonding and rapid setting of ceramic tiles, stone materials, fibre-cement, concrete and any other building material on all types of substrates normally used in construction. Mapei Kerapoxy CQ may also be used to grout unglazed klinker, stone, polished porcelain or porcelain in contrasting colours. Always apply a small sample of Mapei Kerapoxy CQ in a trial area before using the product on wider surfaces.

Some application examples:

- Grouting materials with an uneven surface where it would be difficult to apply and clean traditional epoxy mortar.

- Grouting of floor tile finishes in the foodstuffs industry (dairies, cheese factories, abattoirs, breweries, wineries, preserves factories, etc.), shops and environments where a high level of hygiene is required (ice-cream parlours, butchers shops, fishmongers, etc.).

- Grouting of anti-bacterial tiles.

- Grouting of surfaces where a high protection against the formation and proliferation of micro-organisms is required.

- Grouting tiles on laboratory benches, kitchen worktops, etc.

- Grouting industrial floor tile finishes (galvanizing plants, tanneries, battery rooms, paper works, etc.), where high mechanical strength and a high resistance to attack by acids is required.

- Grouting swimming pools, especially recommended for pools containing spa or sea water.

- Grouting floor tile finishes in steam rooms and Turkish baths.

- Acid-resistant bonding of tiles (used as an adhesive in compliance with class R2 specification according to EN 12004 standard).

- Bonding marble doorsteps and window-sills.

- Bonding tiles in plastic reinforced by fibre glass swimming pools.

- Bonding special pieces of tiles.

Coverage:

Use the grout calculator below to estimate how much grout you will need for your application.

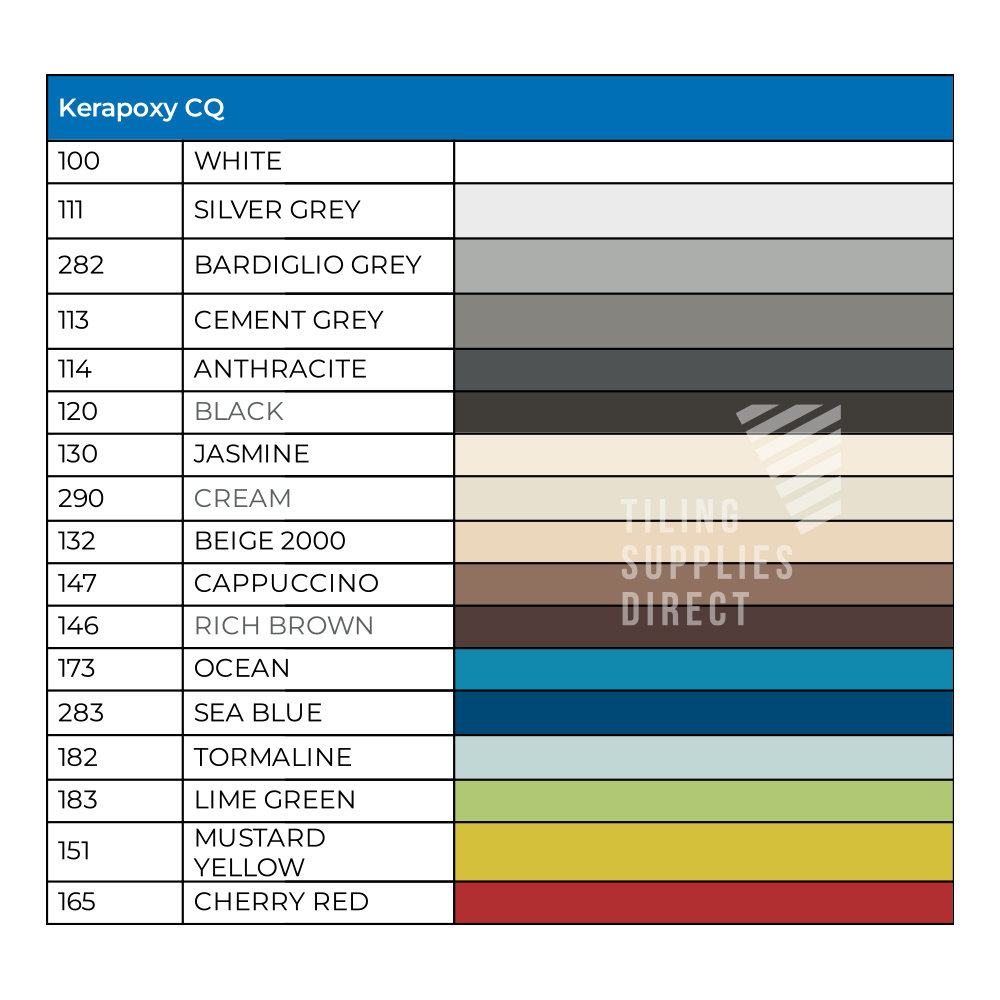

Colours:

Mapei Kerapoxy Epoxy CQ Tile Grout is available in 17 colours: 100 White, 111 Silver Grey, 113 Cement Grey, 114 Anthracite, 120 Black, 130 Jasmine, 132 Beige 2000, 147 Cappuccino, 146 Rich Brown, 151 Mustard Yellow, 165 Cherry Red, 173 Ocean Blue, 182 Tormaline, 183 Lime Green, 282 Bardiglio Grey, 283 Sea Blue, 290 Cream. All colours are supplied in 3kg tubs.

Technical Characteristics:

Mapei Kerapoxy CQ is a two-component, epoxy resin-based product, with silica sand and other special components. It has excellent resistance to acids and is very easy to clean. Mapei Kerapoxy CQ has a bacteriostatic agent, preventing from the proliferation of bacteria and the formation of mould on the surfaces of grouts, making tiled surfaces hygienic and safe, thanks to the innovative BioBlock® technology developed as a result of Mapei research.

This is a product with very low emission of volatile organic compounds and is classified Emicode EC1 R Plus by GEV when used for grouting. When applied correctly, it produces tile joints with the following characteristics:

- Excellent mechanical strength and resistance to chemicals, therefore excellent durability;

- Smooth and compact, surface finish which is non-absorbent and easy to clean; guarantees a high level of hygiene and blocks the formation of mildew and mould;

- High degree of hardness, excellent resistance to heavy traffic;

- No shrinkage and, therefore, no cracking;

- Uniform colour, resistant to atmospheric agents;

- Excellent workability, highly improved compared with traditional epoxy mortars thanks to its creamy consistency, which guarantees faster application times and makes it easier to clean the surfaces, with less waste and easier to obtain a good finish.

Recommendations:

- Even if it already seems clean after passing over the surface with a rubber float, always clean the surface using a Scotch-Brite® pad (or Kerakoll Cleaning Pad) and water, to emulsify traces of resin on the surface which could otherwise modify the final surface finish.

- Use Kerapoxy IEG to grout ceramic and where floor finishes will be subject to attack by oleic acids (ham curers, sausage factories, oil mills, etc.) and aromatic hydrocarbons.

- Use a flexible sealant from the Mapei range (such as Mapesil AC, Mapesil LM or Mapeflex PU45 FT) for flexible expansion joints or for joints subject to movement.

- Mapei Kerapoxy CQ does not guarantee perfect bonding if the edges of the tiles are wet or contaminated with cement, dust, oil, grease, etc. during grouting.

- Do not use Mapei Kerapoxy CQ to grout terracotta tiles, the finish of the tiles may be altered.

- Always carry out preliminary tests before grouting stone or ground porcelain with a porous or rough surface.

- Do not add water or solvents to Mapei Kerapoxy CQ to increase its workability.

- Use the product at temperatures between +12°C and +30°C. However, at temperatures below +15°C application may be more difficult.

- The packages are pre-dosed and, therefore, it is not possible to make mixing errors if all the contents are mixed together. Do not rough guess the quantities when mixing the two components: hardening will be compromised if the catalysing ratio is wrong.

- If hardened and Mapei Kerapoxy CQ has to be removed from the joints, use an industrial hot air blower. If hardened localized residues of the product remain bonded to the tiles, use Pulicol 2000 for cleaning.

Application:

- Preparation of the joints: The joints must be clean, free of dust and free from adhesive to at least 2/3 of the thickness of the tiles. Any adhesive or mortar which has seeped into the joints while laying the tiles must be removed while still fresh. Before grouting, make sure the installation mortar or adhesive has set and most of the moisture has been lost. Mapei Kerapoxy CQ is not harmed by damp from the base, but the joints must not be wet when grouting.

- Preparation of the mix: Pour the catalyser (part B) into the container of part A and mix well until a smooth paste is obtained. We recommend using a low-speed electric mixer to guarantee perfect blending, and to avoid overheating of the mix which would reduce working times. Use the mix within 45 minutes of preparation.

- Application: Spread Mapei Kerapoxy CQ over the tiled surface with a Mapei grout float (or Kerakoll Rubber Grout Float for epoxy grout), making sure that the joints are filled right down to

the bottom. With the edge of the same float, strike off excess material. - Finish: After grouting with Mapei Kerapoxy CQ, floor finishes must be cleaned while the grout is still “fresh”.

Cleaning of the joints may be carried out using a small amount of water and an abrasive sponge for cleaning joints (such as Scotch-Brite® or Kerakoll Cleaning Sponge), followed by a cellulose sponge (Kerakoll Cellulose sponge, for example), taking care to avoid removing grout from the joints. The sponge must be saturated with water when cleaning finishes.

The residual liquid may be removed with the same sponge, which must be replaced when it becomes too impregnated with resin, and the same technique may be used when finishing off the grouted joints.

After the finishing operation, it is very important that no traces of Mapei Kerapoxy CQ remain on the surface. Once hardened, it is very difficult to remove. Therefore, rinse the sponge often with clean water during cleaning. In the case of very large floor surfaces, finishing may be carried out by wetting the surface and using a single-head rotary machine with special abrasive felt disks such as Scotch-Brite®. Residual liquid may be drawn off using a rubber squeegee. Mapei Ultracare Kerapoxy Cleaner for epoxy grout (special cleaning solution for epoxy grout) may also be used for the final cleaning cycle and may also be used to remove thin residues of grout up to several hours after application. In this case, the product must be left to react for longer (at least 15-20 minutes).

The efficiency of Mapei Kerapoxy Cleaner depends on the amount of residual resin and how much time has passed since application. Cleaning must always be carried out while the product is still “fresh” as described above.

Ready for use:

At +20°C, floors are ready to accept light foot traffic after 12 hours. Floors are fully ready for use after 3 days. Surfaces can also undergo chemical attack after 3 days.

Technical Data:

Consistency: Component A: thick paste Component B: gel

Colour: available in 19 different colours

Density (g/cm³): 1.85 0.98

Dry solids content (%): 100 100

Brookfield viscosity (mPa·s) 1,200,000 250,000

EMICODE (as a grout): EC1 R Plus – very low emission

Mix ratio: component A : component B = 9 : 1

Consistency of mix: creamy paste

Density of mix (kg/m³): 1,600

Pot life of mix: 45 minutes

Application temperature range: from +12°C to +30°C

Open time (as an adhesive): 30 minutes

Adjustability time (as an adhesive): 60 minutes

Set to light foot traffic: 12 hours

Ready for use: 3 days

Click here to view this product on the manufacturers website.

Reviews

There are no reviews yet