Description

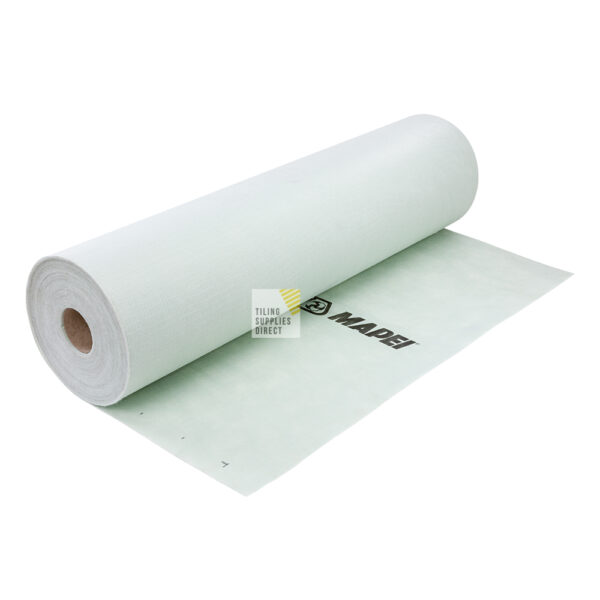

Kerakoll Biotex Anti Crack Matting is a reinforced anti-cracking sheet matting, for evening out tensile and sheer movements between the substrate and the surface finish. Also suitable for use as an anti-cracking product for tongue-and-groove hardwood floors on critical substrates. For internal floors.

Available in 1m x 50m rolls, or per linear metre (supplied as a single roll).

Kerakoll Biotex Anti Crack Matting is designed for laying onto suitable substrates prior to the subsequent laying of ceramic tiles of all kinds, large formats, porcelain tiles, clinker and natural stone, using mineral adhesives from the Bio range.

Product Features:

• To reduce tensile and shear movements between the substrate and the surface finish

• Greater safety on critical and old substrates

• Flexible and long-lasting

• Only 0.65 mm thickness

Use

Kerakoll Biotex Anti Crack Matting is for use with interior floor coverings only. Suitable for:

– suitable load-bearing substrates for laying, such as thoroughly dried concrete and cement based screeds (CT)

– old coating materials made of ceramic tiles and natural stone

– thoroughly dried load-bearing anhydrite screeds (CA)

– levelling products

– mixed, wood, cast asphalt substrates

Installation:

Preparation of substrates:

Irregular substrates must be levelled before laying Kerakoll Biotex Anti Crack Matting, for example using a self-levelling product such as Keratech Eco R30 or a thixotropic levelling product such as Keralevel Eco LR. Absorbent substrates must first be treated with Primer A Eco, while non-absorbent substrates must be treated with Keragrip Eco.

Installation:

Anti-cracking for ceramics tiles and natural stone: Apply an adhesive from the Bio range to the prepared substrate, using a 4 – 6 mm notched trowel. Then apply the Kerakoll Biotex Anti Crack Matting on the still fresh adhesive, spreading it out without any creases while pressing it. When more than one sheet has to be laid, always allow for an overlap of 5 cm. The elastic joints in the building structure must also be repeated in the surface coating. Perimeter and fractionising joints must be incorporated for surface coatings. Lay the surface coating, taking care to ensure that the back of the tiles is completely coated with an adhesive from the Bio range, applied using a toothed spreader of a type suited to the size of the tile. It is not necessary to apply a coat of primer before laying.

Anti-cracking for hardwood floors (with tongue and groove): The substrate must correspond to the requirements of DIN 18356, laying of hardwood floors. For bonding the anti-cracking sheet, hardwood floor adhesives Slc® Eco L34 Plus, Slc® Eco L34 Flex New, Slc® Eco L34 or Slc® Eco L34 Rapid must be used. Before final gluing of hardwood floors allow a drying time of at least 24 hrs.

Technical Data:

Material: PET polyester nonwoven fabric

Colour: slightly greenish white

Roll format length: 50 m; width 1 m

Thickness: ≈ 0.65 mm

Weight: ≈ 150 g/m2

Storage: in a dry place

Click here to view this product on the Manufacturers website.

It does the job its supposed to do at a reasonable price